STARKE INDUSTRIES cc

Est. 1994

Industrialization Through Innovation

about

STARKE INDUSTRIES cc - Est.1994

With our own initiative and the latest technology, it has given us the capacity to design, produce and improve locally manufactured equipment and machines required to perform complicated tasks and are ready and capable of taking on new challenges in machine design, fabrication and custom machining.

Our products has proved that we are able to establish ourselves as leading solution providers and global innovators. We will continue and serve the South African Automotive, Agricultural and Packaging Industry, with optimization of assets. Our main focuses are to create localized, purpose-built equipment for any unique requirement and to improve and optimize your requirement with personalized, turnkey solutions.

Starke Industries is built on technical excellence combined with commitment to the highest standards of service, partnering with clients through each stage of project development while offering a fully comprehensive service.

our mission, vision & value

Is to create localized purpose built equipment for any unique requirements and to improve and optimize requirements with personalized turnkey solutions.

OUR VISION

To be the most flexible company that improves industrialization innovation.

OUR VALUE

We strive for excellence through continuous improvement and will continue to serve the South African Automation, Agriculture and Packaging Industry with optimization of assets.

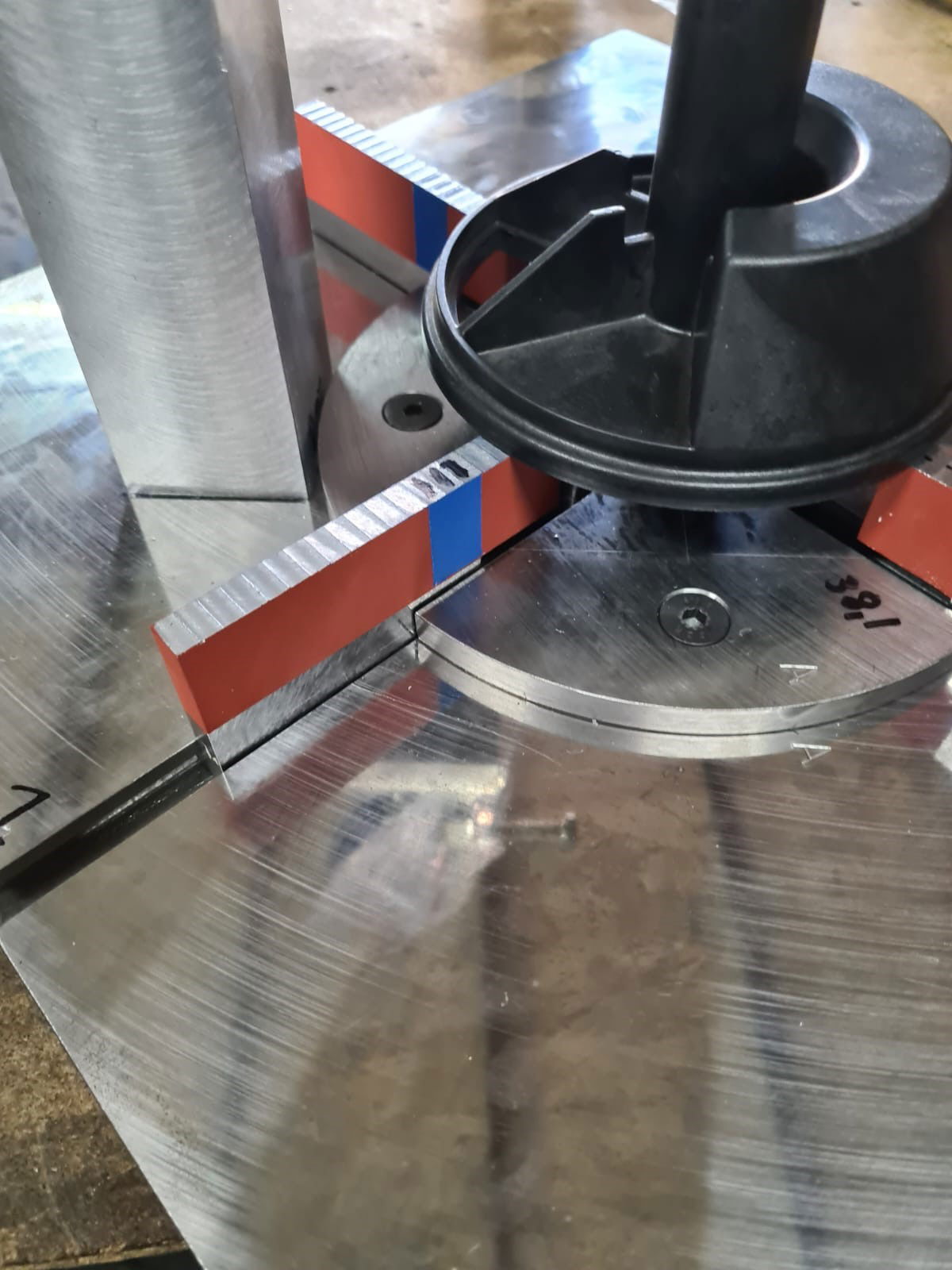

awards

The main purpose of this development was to improve welding on complete exhaust systems. By cleaning individual components more efficiently and the client benefitted with minimized welding rejects.

Furthermore, this machine was designed and equipped to accommodate multiple and various shapes, sizes and diameters as parts are cleaned internally as well as externally.

agriculture

Agriculture

automotive

Automotive

f m c g

F M C G

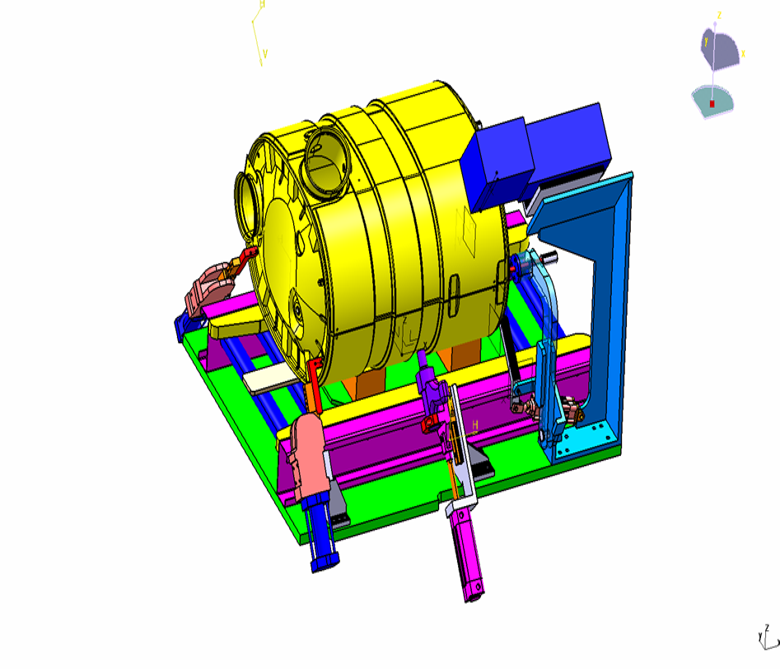

Pallet inverter

Starke Industries design and manufacture reliable & efficient forklift pallet inverters with an innovative solution. Inverter operated by a forklift driver; No need to re-shrink wrap; Low Maintenance; On-site Training; Possibility for digitizing and preventative maintenance & Localized

Rinser

As Starke Industries aim to improve reliability and increase growth for businesses, this project serves as an additional improvement for a production line. This development serves the purpose of a pre-cleaning station to rinse off all large articles and dirt to ease the washing process of the crate washer. This machine was locally designed and manufactured. This machine is suggested for the bottling industry.

Read morerenewable energy

Renewable energy

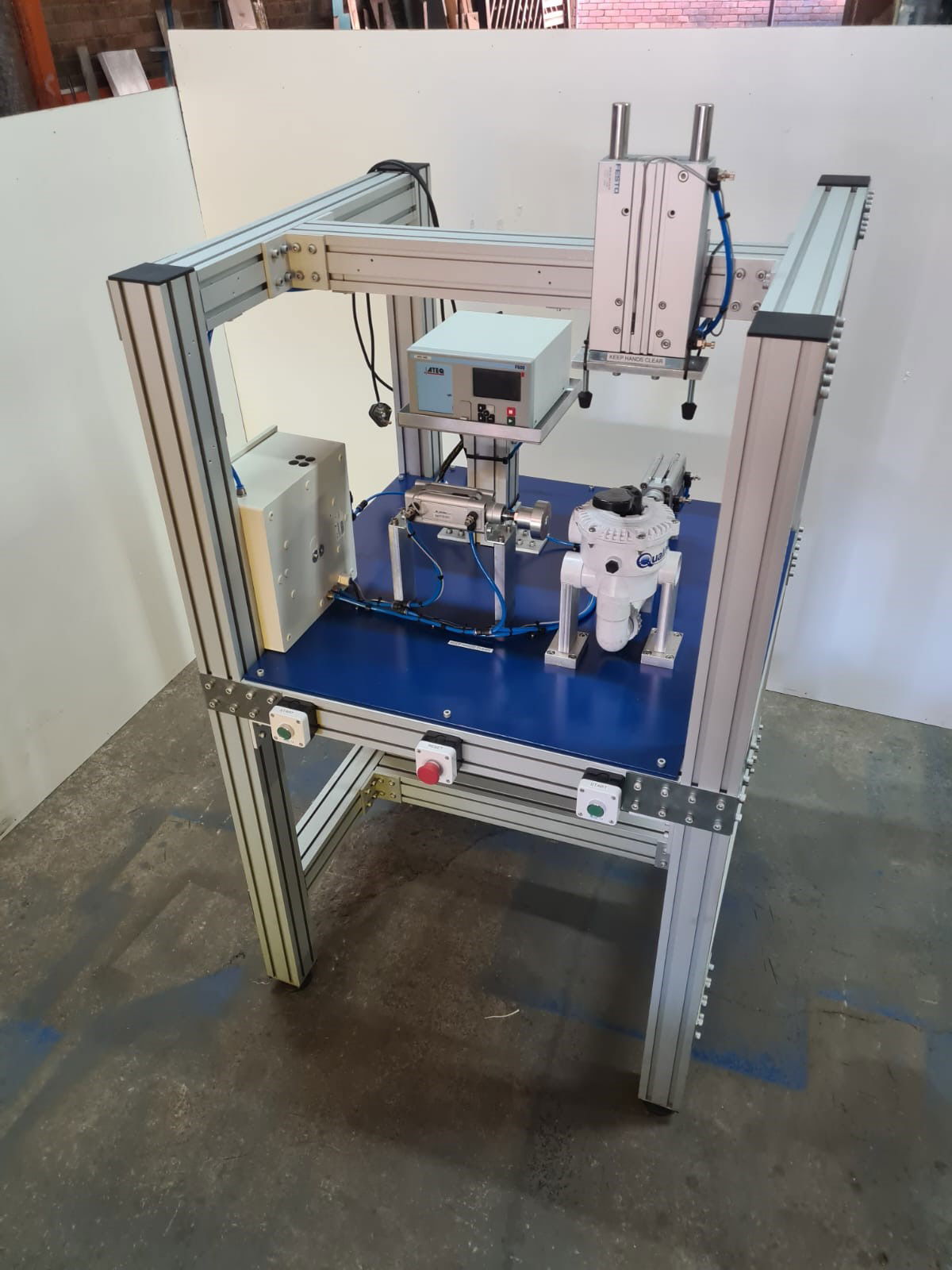

automation special purpose machines

PIN ASSEMBLY MACHINE

NUT INSERTION MACHINE

SPECIAL PURPOSE MACHINE - ULTRASONIC WELDING MACHINE

CONTROL SYSTEMS

AUTOMATED GLUING MACHINE

FULLY AUTOMATIC ROBOTIC PALLETISER

GRIPPER

ROBOT END OF ARM TOOL • Pick and Place • Vacuum System • Welding Robots • Alternatively, we can design innovative solutions for the agriculture, packaging and automotive industries.

fabrication

- We offer practical in-house training for apprentices.

- This includes all mechanical related work for tool makers and future machinists.

- We partner with PTSA and other relevant organisation.

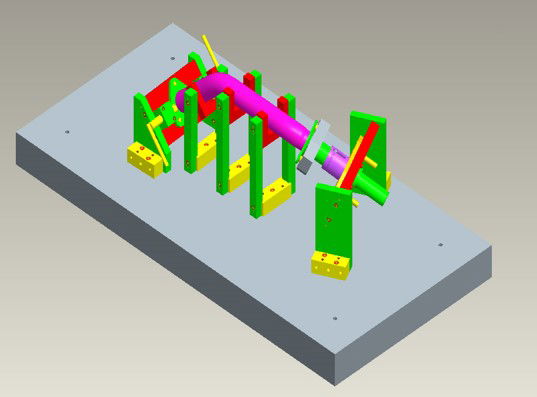

inspection equipment

We design and manufacture inspection equipment for any parts and any industry.

MANUAL INSPECTION JIGS

LEAK TESTER

VISION INSPECTIONS SYSTEM

MANUAL INSPECTION JIG

industrial engineering design

Industrial Engineering Design

Our company design automated equipment in order to assemble, check and validate any parts. We implement international RULA requirements on all equipment and simulate worker ERGONOMICS.

manual assembly equipment

Mechanical Manipulation Arm

Starke Industries designed, manufactured, and installed a mechanical arm manipulator with vacuum systems for Hyundai South Africa to assemble CKD vehicles.

Manual Assembly Equipment

Design and manufacture Manual Assembly Equipment for delicate processes.

Digitized Manual Assembly System.

We also supply a Digitized Manual Assembly System for any equipment requiring data storage.

material handling

Conveyors

Pallets

Shelving

Material handling conveyor

Spiral conveyor

Mixing Tank

Efficient pallet Invertor

Starke Industries design and manufacture reliable & efficient forklift pallet inverters with an innovative solution.

maintenance & support services

Planned maintenance:

- Inspection of Equipment

- Hydraulics

- Mechanical

- Electrical

- Create and compile sketches

- Localize parts

- Replace or rebuilt components

- Implement T.P.M.

optimizor

We use the latest hydraulic, pneumatic and control systems in order to optimize equipment.

In most cases we use existing mechanical structures and upgrade them. We replace all the operational parts.

All equipment must comply with the latest industry safety standards.

PRIMARY TECHNIQUES IMPLEMENTED:

- Infrared

- Vibration

- Ultra Sound

- Oil Analysis

- Air leaks

relocation of production lines

Relocation of complete production facilities. Our services includes mechanical, electrical and rigging. Our approach is holistic and we offer end to end solutions.

Before relocation

After relocation

upgrades

washing and rinsing equipment

Vegetable washer

These solutions include conveyor systems from thoroughly washing and dosing lettuce as well as cutting corn in different lengths. Other solutions include sorting and packaging vegetables and other process equipment designed for quality vegetable processing.

Rinser

As Starke Industries aim to improve reliability and increase growth for businesses, this project serves as an additional improvement for a production line. This development serves the purpose of a pre-cleaning station to rinse off all large articles and dirt to ease the washing process of the crate washer. This machine was locally designed and manufactured. This machine is suggested for the bottling industry.

Big Dipper-Industrial washing

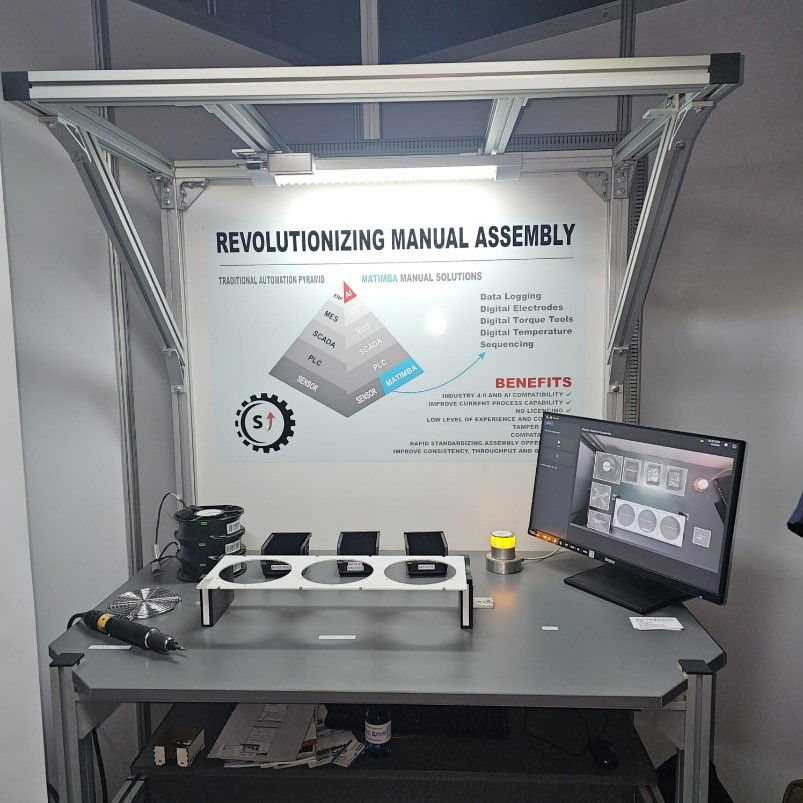

operator guidance system (ogs)

OPERATOR GUIDANCE SYSTEM

MATIMBA, an industrial DOJO which helps individuals learn complex skills, practices, and tools on -the-job to develop better products faster with a )% fail rate! ROI is extremely important, especially in the industrial sectors. How will your company and employees benefit by our integration of AI and AR into ML, so your bottom line becomes your biggest asset? What do we offer?

- Operator guidance system (OGS)

- Transformation of your manual workstations into digital environments

- Deploying Augmented Reality (AR)

- Facilitating the adoption of sustainable manufacturing

An Operator Guidance System (OGS) is a digital solution designed to assist human operators in performing complex tasks with greater precision, efficiency, and consistency, particularly in manufacturing and assembly environments. Think of it as a "sat nav for your production line," providing step-by-step instructions and real-time feedback.

Here's a breakdown of what an OGS typically entails and its benefits: Key Features and Components:

- Digital Work Instructions: Replaces paper manuals with clear, interactive, and often visual step-by-step instructions displayed on screens. These can include images, videos, and augmented reality (AR) overlays.

- Real-time Feedback and Validation: Uses sensors, vision systems (computer vision), and smart tools to monitor the operator's actions and provide immediate feedback. This helps prevent errors by alerting operators to incorrect steps, missing parts, or improper tool usage.

- Pick-to-Light Systems: Guides operators to the correct parts for assembly using illuminated bins or indicators, ensuring the right components are picked at each stage.

- Socket Trays: Highlight and unlock the specific socket needed for a task, streamlining the assembly process.

- Barcode/RFID Scanners: Used to load relevant work instructions, confirm correct parts, and manage inventory.

- Augmented Reality (AR): Overlays digital information directly onto the real-world workspace, providing immersive guidance and making complex tasks easier to understand.

- Data Collection and Analytics: Records all actions for traceability, identifies bottlenecks, tracks operator performance, and provides data for continuous improvement initiatives.

- Integration: Can integrate with existing business systems like Manufacturing Execution Systems (MES) or Programmable Logic Controllers (PLCs).

Benefits of Implementing an OGS:

- Error Reduction: Significantly minimizes human error, which is a major cause of quality defects and rework. This leads to higher quality products and reduced scrap.

- Increased Productivity: Streamlines workflows, reduces cognitive load on operators, and speeds up task completion, leading to improved throughput and efficiency.

- Faster Training and Onboarding: Provides easy-to-follow instructions, allowing new or temporary workers to become proficient much faster, reducing training durations.

- Enhanced Quality Assurance: Ensures tasks are performed correctly and consistently, leading to standardized processes and better product quality.

- Improved Traceability: Logs all actions and data, providing a complete history of the assembly process for quality control and regulatory compliance.

- Flexibility and Adaptability: Supports high-mix, low-volume production environments by allowing for easy customization of instructions for different product variants.

- Knowledge Preservation: Digitizes operational knowledge, reducing dependency on individual expertise and making it easier to share best practices.

- Reduced Costs: Lowers costs associated with rework, scrap, and training.

In essence, Operator Guidance Systems bridge the gap between human operators and increasingly complex manufacturing processes, empowering the workforce, improving quality, and driving overall operational excellence.

A workplace DOJO is a dedicated environment where employees converge to learn, practice, and refine their skills through immersive and hands-on training sessions.

We are making use of Augmented reality (AR), also known as mixed reality (MR), is a technology that overlays real-time 3D-rendered computer graphics onto a portion of the real world through a display, such as a handheld device.

This experience is seamlessly interwoven with the physical world such that it is perceived as an immersive aspect of the real environment. In this way, augmented reality alters one's ongoing perception of a real-world environment, compared to virtual reality, which aims to completely replace the user's real-world environment with a simulated one.

Augmented reality is typically visual, but can span multiple sensory modalities, including auditory, haptic, and somatosensory.

our clients

24/7 support

24/7 Support to all manufacturing facilities incl.

- Mechanical

- Electrical

- Hydraulic

- SLA on request

- PLC Back-up

contact us

- 16 Lever Road, Rosslyn, Akasia, Gauteng, South Africa

- Unit 2, Rosslyn East, 0200

- +27-082 898 7170 - Director: Mr. Fritz Moolman

- fritzmoolman@mweb.co.za

- Operating hours: Monday - Thursday 07:30 - 16:30 Friday 07:30 - 14:00 Saturday Closed Sunday Closed Public Holidays Closed

24 Hour Service & support Contact no.: 082 898 7170