operator guidance system (ogs)

OPERATOR GUIDANCE SYSTEM

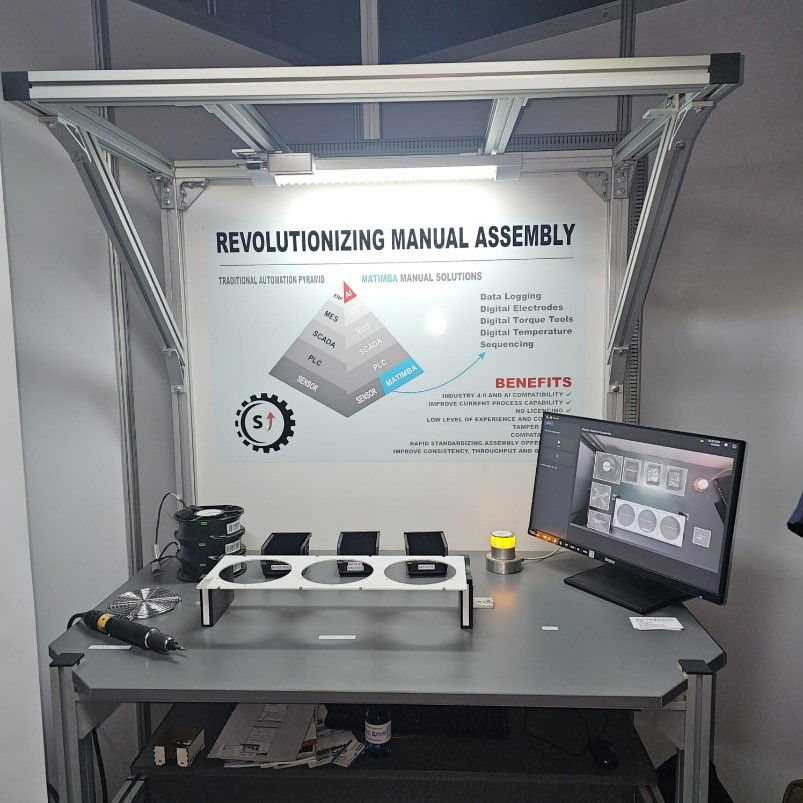

MATIMBA, an industrial DOJO which helps individuals learn complex skills, practices, and tools on -the-job to develop better products faster with a )% fail rate! ROI is extremely important, especially in the industrial sectors. How will your company and employees benefit by our integration of AI and AR into ML, so your bottom line becomes your biggest asset? What do we offer?

- Operator guidance system (OGS)

- Transformation of your manual workstations into digital environments

- Deploying Augmented Reality (AR)

- Facilitating the adoption of sustainable manufacturing

An Operator Guidance System (OGS) is a digital solution designed to assist human operators in performing complex tasks with greater precision, efficiency, and consistency, particularly in manufacturing and assembly environments. Think of it as a "sat nav for your production line," providing step-by-step instructions and real-time feedback.

Here's a breakdown of what an OGS typically entails and its benefits: Key Features and Components:

- Digital Work Instructions: Replaces paper manuals with clear, interactive, and often visual step-by-step instructions displayed on screens. These can include images, videos, and augmented reality (AR) overlays.

- Real-time Feedback and Validation: Uses sensors, vision systems (computer vision), and smart tools to monitor the operator's actions and provide immediate feedback. This helps prevent errors by alerting operators to incorrect steps, missing parts, or improper tool usage.

- Pick-to-Light Systems: Guides operators to the correct parts for assembly using illuminated bins or indicators, ensuring the right components are picked at each stage.

- Socket Trays: Highlight and unlock the specific socket needed for a task, streamlining the assembly process.

- Barcode/RFID Scanners: Used to load relevant work instructions, confirm correct parts, and manage inventory.

- Augmented Reality (AR): Overlays digital information directly onto the real-world workspace, providing immersive guidance and making complex tasks easier to understand.

- Data Collection and Analytics: Records all actions for traceability, identifies bottlenecks, tracks operator performance, and provides data for continuous improvement initiatives.

- Integration: Can integrate with existing business systems like Manufacturing Execution Systems (MES) or Programmable Logic Controllers (PLCs).

Benefits of Implementing an OGS:

- Error Reduction: Significantly minimizes human error, which is a major cause of quality defects and rework. This leads to higher quality products and reduced scrap.

- Increased Productivity: Streamlines workflows, reduces cognitive load on operators, and speeds up task completion, leading to improved throughput and efficiency.

- Faster Training and Onboarding: Provides easy-to-follow instructions, allowing new or temporary workers to become proficient much faster, reducing training durations.

- Enhanced Quality Assurance: Ensures tasks are performed correctly and consistently, leading to standardized processes and better product quality.

- Improved Traceability: Logs all actions and data, providing a complete history of the assembly process for quality control and regulatory compliance.

- Flexibility and Adaptability: Supports high-mix, low-volume production environments by allowing for easy customization of instructions for different product variants.

- Knowledge Preservation: Digitizes operational knowledge, reducing dependency on individual expertise and making it easier to share best practices.

- Reduced Costs: Lowers costs associated with rework, scrap, and training.

In essence, Operator Guidance Systems bridge the gap between human operators and increasingly complex manufacturing processes, empowering the workforce, improving quality, and driving overall operational excellence.

A workplace DOJO is a dedicated environment where employees converge to learn, practice, and refine their skills through immersive and hands-on training sessions.

We are making use of Augmented reality (AR), also known as mixed reality (MR), is a technology that overlays real-time 3D-rendered computer graphics onto a portion of the real world through a display, such as a handheld device.

This experience is seamlessly interwoven with the physical world such that it is perceived as an immersive aspect of the real environment. In this way, augmented reality alters one's ongoing perception of a real-world environment, compared to virtual reality, which aims to completely replace the user's real-world environment with a simulated one.

Augmented reality is typically visual, but can span multiple sensory modalities, including auditory, haptic, and somatosensory.